Salomon

Reduce physical samples

Streamline & optimize workflows

Break down internal silos

Making product development more sustainable, efficient and collaborative

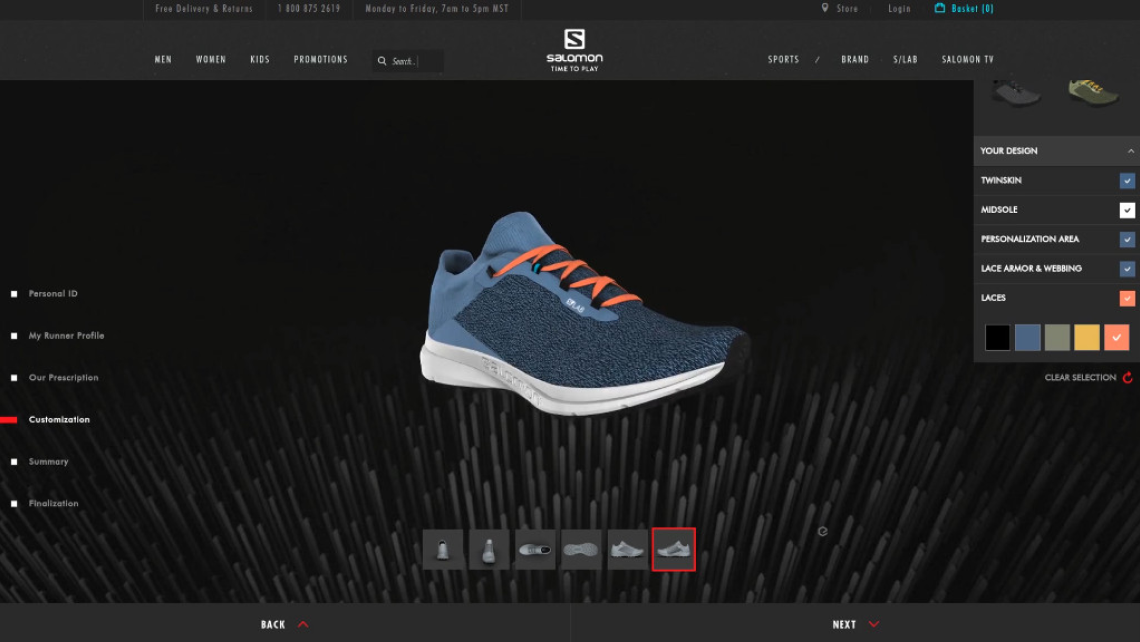

Emersya has been working with Salomon as a 3D technology partner since 2016 when they released their revolutionary SLAB ME:SH configurator. Since launching this first project together, we have been discussing Salomon’s challenges and the potential for using 3D technology in other stages of their product lifecycle workflows. Salomon were looking for a way to streamline and accelerate their internal workflows for designing the different variants in their new product collections. Their designers needed an easy-to-use online solution that would allow them to prepare their variant designs in 3D, then share and review them with members of the wider product design, development, marketing and sales teams.

Like the majority of brands in the footwear industry, Salomon had started to digitize their product design process but were still facing a number of road blocks. For example, although the team would design new product digitally; using CAD (computer-aided design) software to design the sole of the shoe and composition and 2D graphic design software to design the look and feel; in order to visualize and validate the product designs with the rest of the team, lots of physical prototypes still had to be made.

Salomon used to produce thousands of shoe samples per year in order to review all the iterations of the different product variant designs internally. Each iteration is long, as the new prototypes must be produced, shipped and delivered to all the key team members who must then meet to review the new samples, evaluate and adjust their designs and potentially request new samples. This process represented approximately 2 thirds of the brand’s product design workflow, making a new product’s time to market 18-24 months.

Once the designs had been approved, Salomon would order tens of thousands of physical product samples for their sell-in teams to present to their distributors. In total, Salomon were producing on average 40,000 shoe samples every year! The production and shipping of so many physical prototypes and samples is not only expensive but also has a negative impact on the environment. Manufacturing 40,000 shoes requires over 360,000 liters of water, while shipping these samples from the factories to the Salomon HQ generates 660 tons of CO2.

Challenges

Reduce the production of physical samples from 40,000/year to a few thousand

Make the product design process more sustainable and reduce impact on environment

Reduce the costs and risks of logistics (higher than usual during covid)

Speed up time to market by 50%

Automate the low value data compilation tasks to double the time designers spend on creative ones and remove the human margin of error

Involve more stakeholders in the design review to make better business decisions

Solution

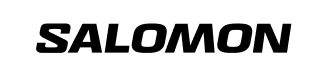

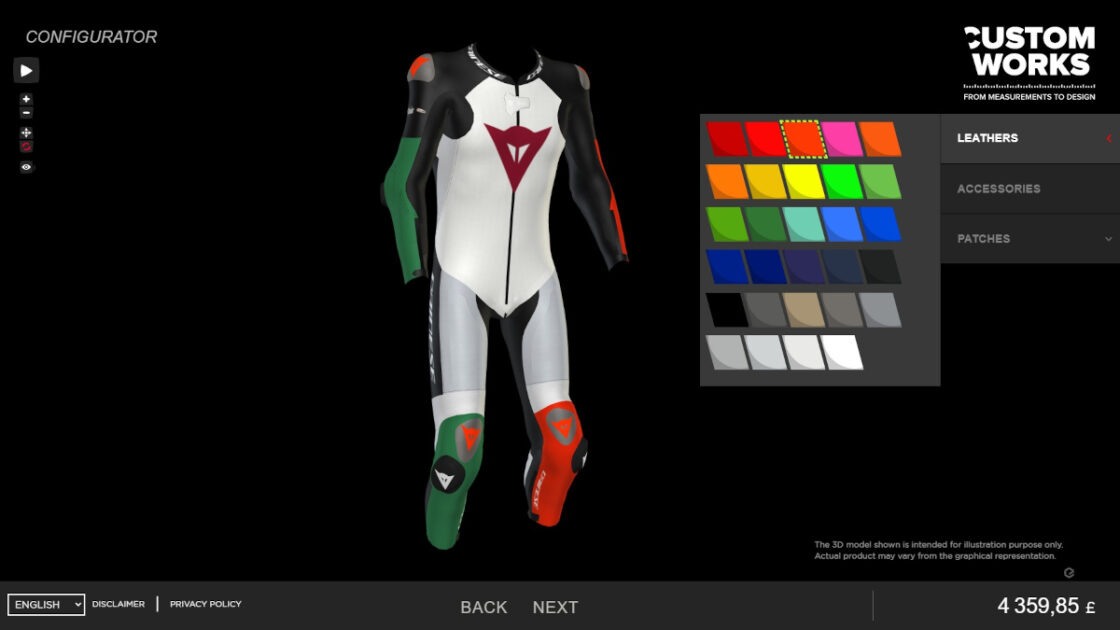

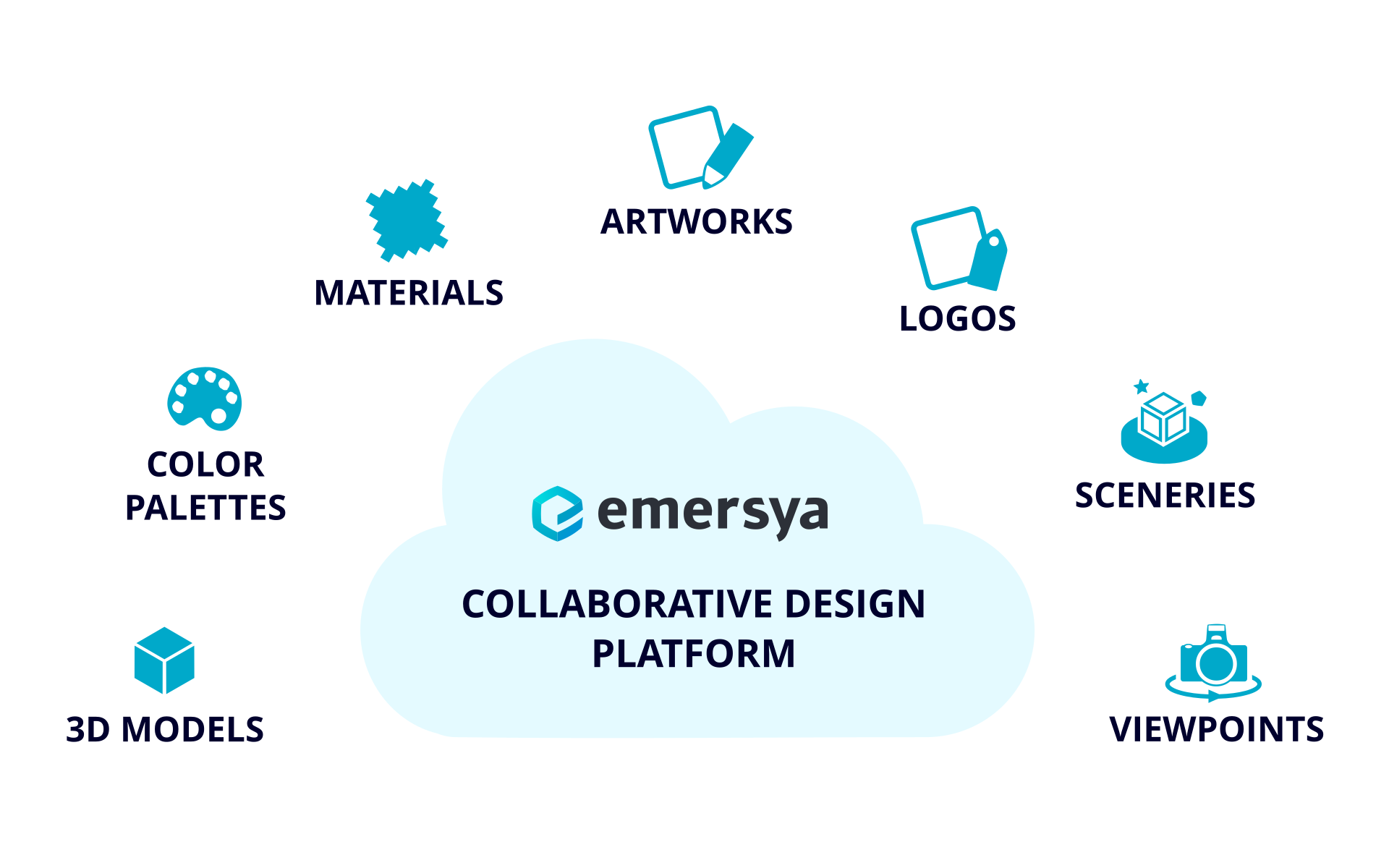

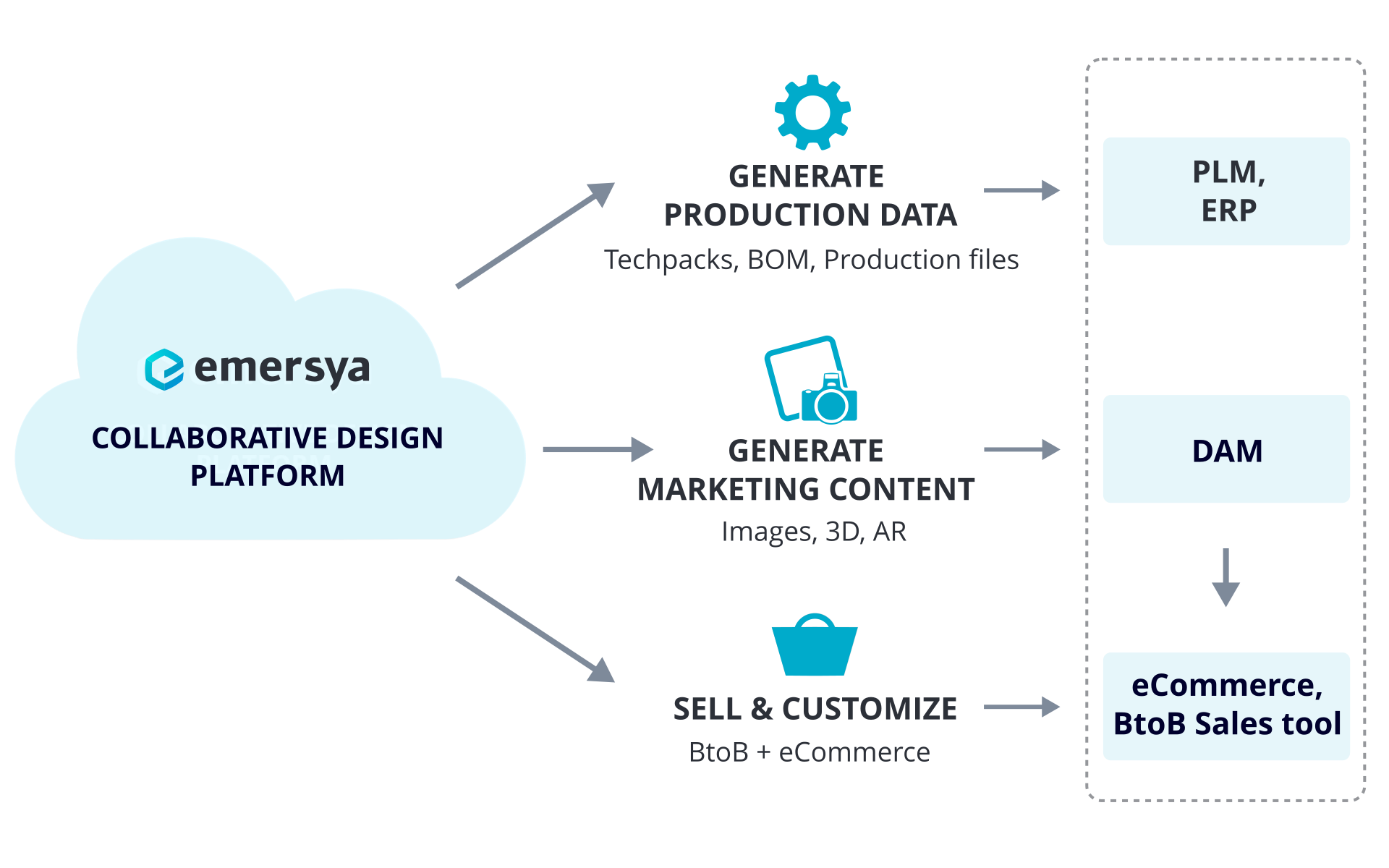

Working closely with Salomon and other brands experiencing similar challenges to those outlined above, Emersya developed an online platform for collaborative product design.

The platform empowers brands to leverage existing digital assets to streamline product ideation workflows and involve extended product development & marketing teams in the digital design process. This provides Salomon with an online, user-friendly solution for designing, reviewing, modifying and approving different product variants in real-time 3D. Once the new designs have been approved, the platform can automatically generate production data and digital marketing content.

1) Publish Assets

Salomon publish their 3D models on the Emersya Platform where they can define the rules of the product parts according to the Bill of Materials (BOM) structure. They can create digital material libraries by importing scanned materials (e.g. in U3M or AxF formats) and Substance materials to Emersya. It is also possible to create materials directly on the platform by importing texture maps and adjusting the 3D parameters. Salomon then set up color palettes for their new product collections. They can do this either manually, by importing from Illustrator (.ase files) or by uploading mood board images from which the platform will extract the dominant colors and all over prints.

2) Validate design concept

Once published on the Emersya Platform, the 3D models can be easily viewed online by any team member. Rather than preparing 2D mockups using Illustrator, the technical designers can share a secure link that will allow their team members to load the design in real-time 3D directly in their web browser, thanks to Emersya’s online viewer. This enables non-technical members of the design team to visualize the new product designs from any angle and to zoom in on the details in order to validate the shape and structure.

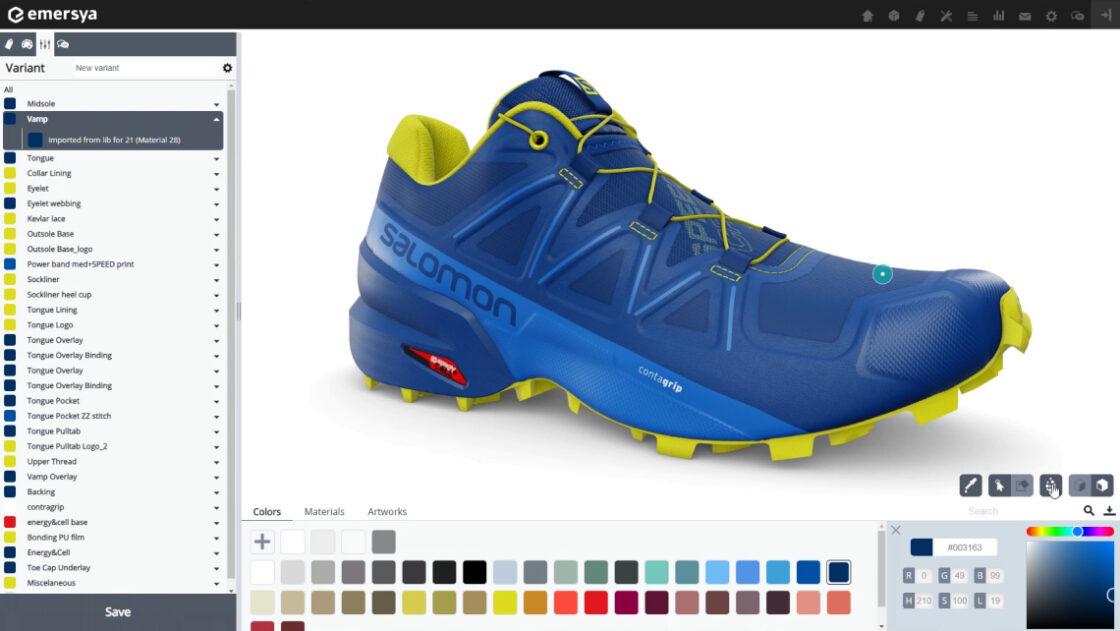

3) Create product variants

Once the product concept and 3D prototype’s shape has been validated, the creative team can start designing the look and feel of the different variants in the product collection. Emersya’s Collaborative Design platform provides designers with an easy-to-use online tool for trying out different colors, materials, all over prints, logos and patches, on any part of the product, all in real-time Interactive 3D.

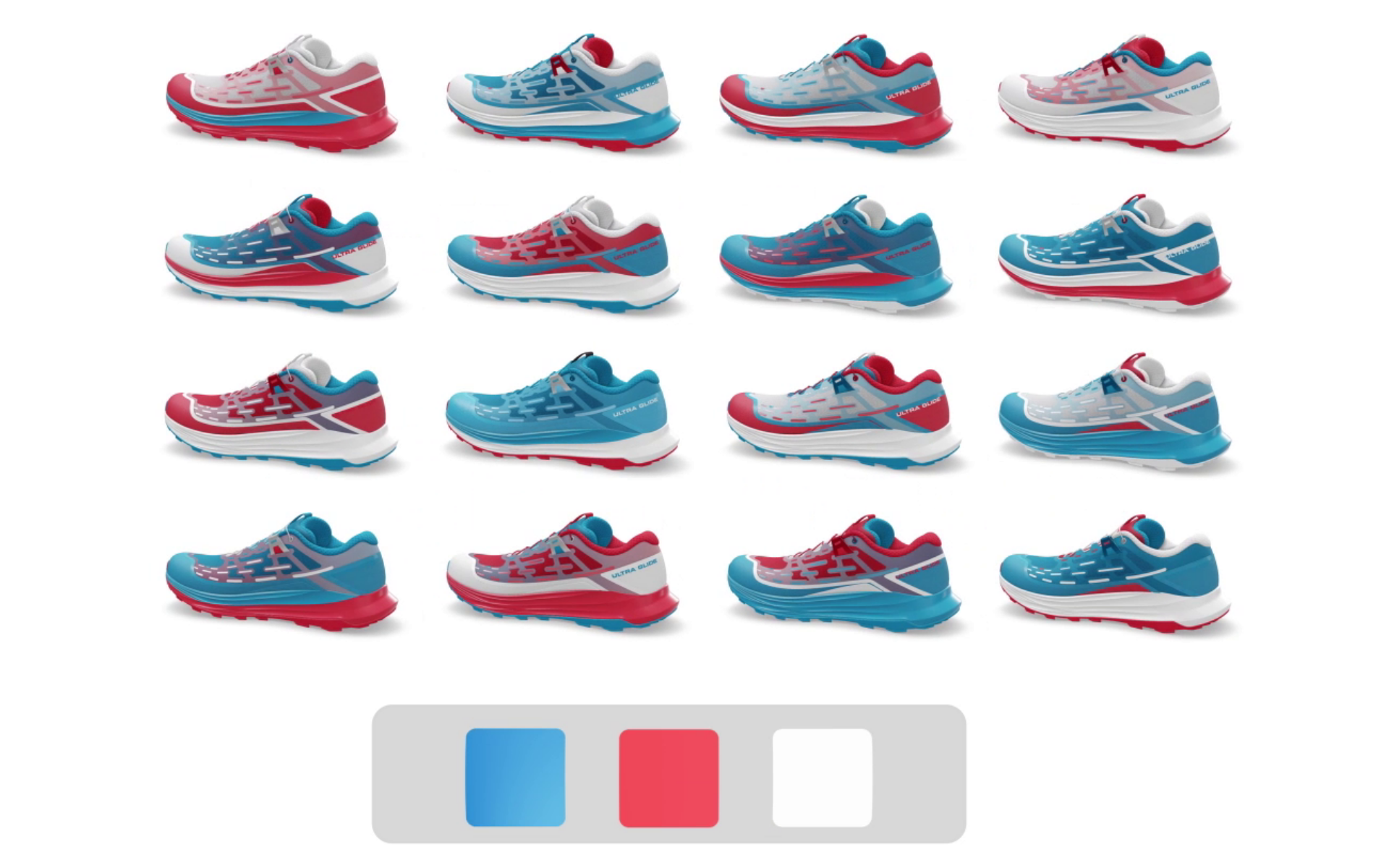

When applying materials, designers can choose to change the color of the material for a color from their palette. The Emersya Platform makes it possible to define the real size of the digital material sample in order to automatically apply it to scale on the product model. The scale, orientation and placement of the material can also be adjusted on the fly using sliders. The “Randomize” feature allows designers to automatically generate a large number of different colorways from a selection of colors in their palette.

Using the Collaborative Design tool Salomon can upload images to apply to their product designs. They can choose whether to use an image as a pattern that should be repeated across the selected part of the product or apply the image as a print or patch on a specific part. The all over prints and logos can be resized, re-positioned and rotated in real-time on the product model.

The Emersya Platform has a built-in animation engine making it possible to prepare multi-state animations for any 3D model published on the platform. Salomon prepare exploded views for their shoes in order to be able to zoom in on the different composite layers separately.

4) Review, Modify, Iterate, Approve

Once a product variant design has been prepared by a member of the Salomon team, they can save their design and share it with the rest of the team. The platform automatically generates a link that can be opened in any web browser on any device, to load the product variant in Emersya’s 3D viewer. The product variant can also be loaded on the Emersya platform by members with a login to the Collaborative Design tool. An ergonomic interface allows team members to add comments about the design and to pin dynamic annotations to a specific part of the 3D model.

Salomon can now carry out their review process online using the Collaborative design solution and the digital twin created on Emersya, instead of producing thousands of physical samples. During online review process, the necessary adjustments can be made to the digital twin much more quickly and easily, greatly reducing the time required for each iteration. At the end of the review process, the different product variant designs can be submitted for rating and approval by a larger part of the product design team.

5) Involve more stakeholders

By using a non-technical, online solution that offers a number of options for sharing the new variant designs in Interactive 3D, Salomon can now easily involve more stakeholders in design reviews. For example, marketing and sales teams can carry out market research using the shareable links to the digital twins and distributors can request and review custom variants, designed exclusively for them. This allows Salomon to get a better tailor their designs to their market and make better business decisions.

6) Generate Marketing material

Aside from their own eCommerce and physical stores, Salomon works with a large number of sportswear distributors. For each new product collection, Salomon’s B2B sales representatives used to meet with retailers in person to present physical product samples. Since 2020, Salomon has had to adapt their processes due to the constraints imposed by the pandemic. Disruptions to the supply chain have led to a complete lack of physical product samples available for preparing marketing content or for use in B2B Sales meetings.

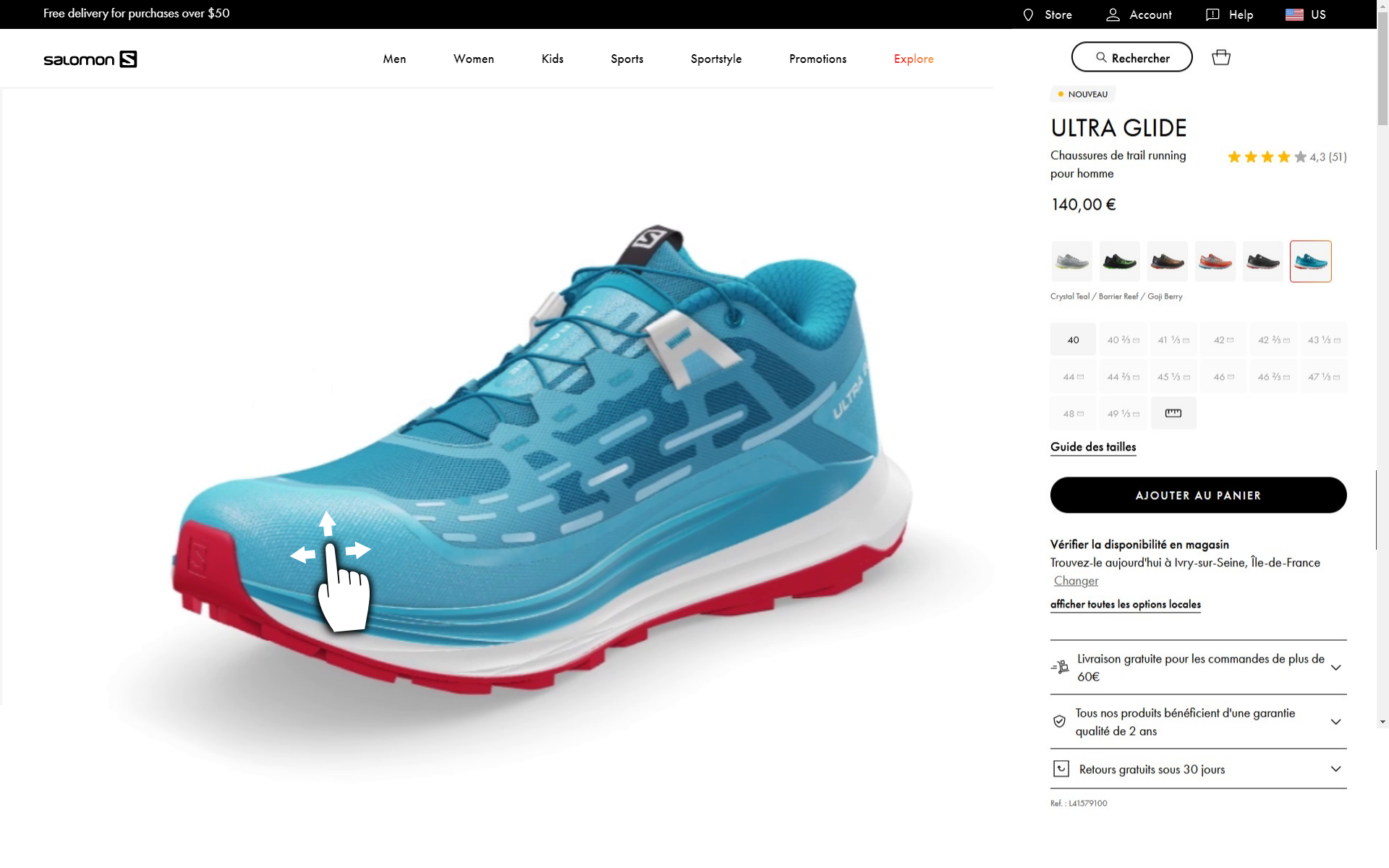

Now, thanks to the Collaborative Design solution, as soon as a variant design is saved on the Emersya Platform, a password restricted url is generated to be able to visualize the digital twin in any web browser. Once a design has been approved, this link can be embedded in any web page, as easily as a YouTube video. This means that Salomon’s marketing team can offer an Interactive 3D visualization experience and share it with their distributors, before the product has even been sent to production! It is also possible to activate the Augmented Reality feature so that the digital twin can be visualized to scale in a product exhibit in a distributor’s boutique.

Salomon also use the Emersya Platform to automate the process of preparing pack-shot images for a number of different viewpoints for all their product variants. This allows them to generate product visuals much more quickly and without relying on the production of physical products and organizing photo-shoots. The pack-shots are uploaded to Salomon’s DAM (Data Asset Management) system, making them available to their sales representatives around the world. This once again reduces the number of physical samples that must be produced as B2B sales presentations of new product collections can be carried out using the Interactive 3D experiences and virtual product photos.

The ability to produce marketing content ahead of production shortens the time to market and makes it possible for the brand to launch the product ahead of production and to better anticipate orders from retailers.

7) Generate Production Data

Once a product variant has been approved, the platform automatically generates the data required by Salomon’s production team, such as the Bill of Materials and Tech Packs. Emersya developed a custom plug-in for Salomon’s PLM (Product Lifecycle Management) system, meaning the data generated by the platform can be automatically sent to update the PLM. This removes the need for the designers to spend time manually filling in data and reduces the margin for error.

About the company

Salomon Group is a French outdoor sports equipment manufacturing company based in Annecy, France. The brand is part of Amer Sports.